- #Generate a test bench with modelsim pe generator

- #Generate a test bench with modelsim pe verification

- #Generate a test bench with modelsim pe code

- #Generate a test bench with modelsim pe download

Download source codeĪyush Mallik is an electronics hobbyist and a circuit designer.Check out the official EngineeringStudents Discord!: discord.gg/EngineeringStudents Average power consumed by PWM output is 3mW, which indicates that the design is also power efficient. Static power dissipation for 34mW (power required to drive the development board) and the power consumed by the oscillator to produce the clock is 1mW. Total power dissipated by the design at an operation frequency of 50MHz is 38mW. This PWM has a maximum operating frequency of 232.504MHz, which allows the most dynamic and fast operation applications to be accommodated. A reset button (G12) is provided on the board to restart the counter, if needed. The On pulse width will change in accordance to 8-bit binary sequence produced by toggling switch positions on the FPGA board.

#Generate a test bench with modelsim pe generator

To verify output, connect an oscilloscope to the output of PWM generator at pin B2. Output is taken from first pin B2 of first expansion header JA. The board provides a 50MHz default clock attached to the FPGA through pin B8 (available at jumper header JP4). To test the circuit for functional verification, program 8-bit input of PWM generator as eight switches (SW0 through SW7) present on FPGA board.

#Generate a test bench with modelsim pe verification

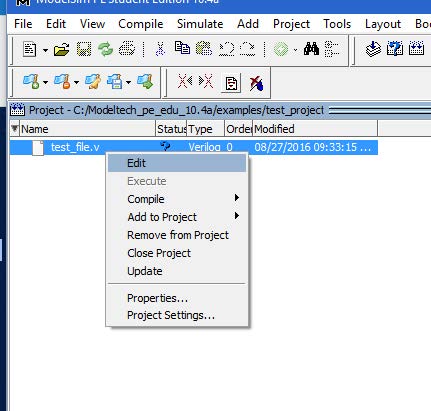

bit file onto the FPGA for verification first and then onto the ROM so that FPGA works as a PWM module whenever powered on. Input PWM_ontime // 8-bit PWM inputĪfter including the necessary files onto the project, select the option to generate a programming file, which creates. Module PWM_generator (PWM_ontime, PWM_out ,

#Generate a test bench with modelsim pe code

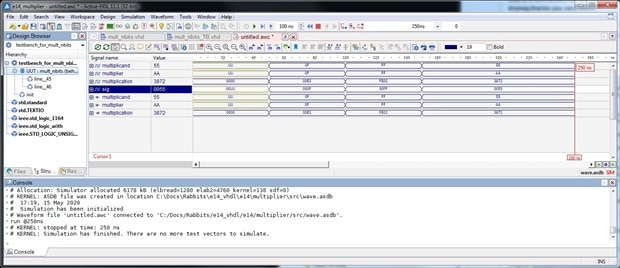

Verilog main code used (PWM_main.v) for PWM generation is given below. Thus, PWM can be achieved by varying the input provided to PWM module. Comparator finds that, current counter value is greater than the value provided to PWM module, therefore output must be pulled low.Ĭhanging input to PWM module will consequently change the threshold value, where transition from high to low state occurs. In the next clock cycle, after the counter has reached 128, counter increments its value to 129(10000001) b. This same paradigm keeps output of the generator pulled high until value of the counter reaches 128 (10000000) b. This prompts the module to pull output of PWM generator high. The module finds that, value of counter is less than the value provided. During the first clock cycle, value of counter and input value to PWM module are compared. Counter is initialised using Reset button, so that output is 0(00000000 b).

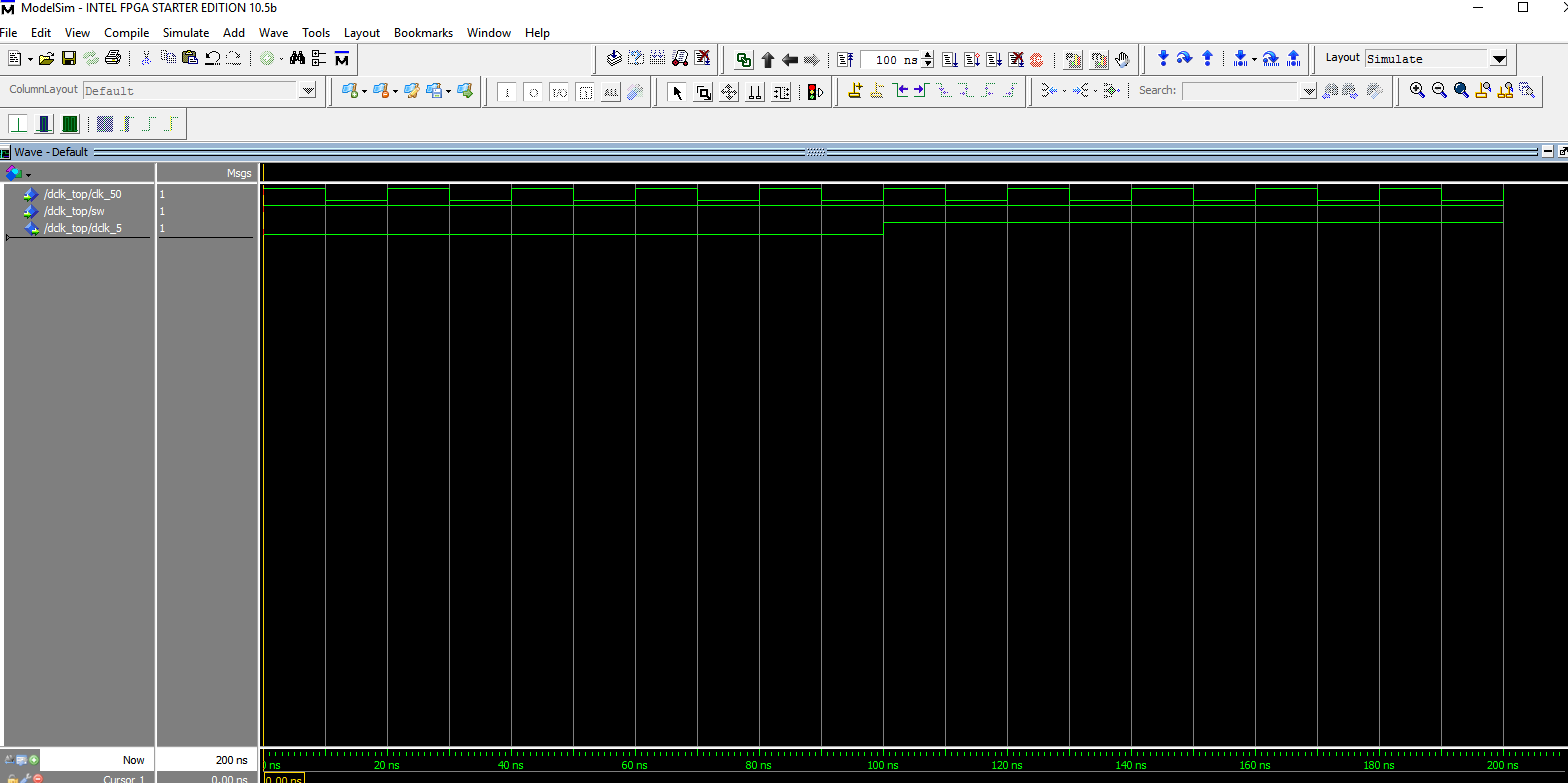

Suppose, input to PWM module is 128 (10000000 b). Let us take a test case to understand the operation. However, if current value of the counter is less than the value given as input to the module, output of PWM generator is pulled high. If current value of the counter is greater than the value given to the module as input, PWM output is pulled low. Input given to PWM module is compared to the current value of the counter using the comparator. Comparator used in the PWM generator is also 8-bit. It increments its value on the positive edge of the clock (positive edge triggered). The microcontroller unit provides 8-bit input into PWM module. Working principle of the generator is simple. PWM generationīlock diagram of the PWM generator is shown in Fig. It is simulated using ModelSim, a multi-language (hardware description language) simulation environment from Mentor Graphics and tested on Basys 2 FPGA development board from Digilent.

This project demonstrates how a simple and fast pulse width modulator (PWM) generator can be implemented using Verilog programming.

0 kommentar(er)

0 kommentar(er)